The holy grail of supply chain optimization is predicting what will be sold, in what quantity, where, and when – with 100% accuracy. Organisations capable of doing that could run the leanest possible supply chain – with minimal inventory levels – while always satisfying customer demand and never stocking out. Unfortunately, such prediction accuracy is impossible to achieve, and for that reason, all organisations must carry some level of inventory to buffer against unexpected changes in demand.

Despite the fact that organisations of all shapes and sizes have gorged themselves on demand planning software over the past few decades, demand forecasting still remains an unsolved problem within most organisations – “unsolved” in that the forecast error is still high, leading to stock-outs, as well as excessive inventory levels and obsolescence.

What is Inventory Replenishment? Definition, Process & More

Inventory replenishment involves restocking or refilling inventory levels in order to maintain a certain level of availability for products or materials. It is a key aspect of inventory management and can be managed using techniques such as setting reorder points, utilizing demand forecasting to predict future demand, and implementing automated replenishment systems.

The goal of inventory replenishment

The goal of inventory replenishment is to achieve a balance between having too much or too little inventory on hand, which is known as just-in-time inventory. By effectively managing inventory replenishment, businesses can ensure that they have the right amount of inventory available to meet customer demand, operate efficiently and keep customers happy.

Inventory replenishment is an important step in managing your inventory. It ensures you always have enough additional stock and raw materials on hand to meet customer demand. But there are many different methods for doing this. In this article we'll look at what inventory replenishment is, why it matters, and some of the most common approaches to performing it.

What Is Inventory Replenishment or Stock Replenishment?

Optimised inventory replenishment systems include all aspects of an organization’s operations, including logistics, finances, human resources, marketing and sales, purchasing, production and quality control, among others. This ensures that there is enough product to meet customer demand.

In order to ensure that there are sufficient supplies of products available to fulfill customer requirements, companies must monitor their inventories carefully. If too much stock is held, it could lead to overstocking and wasted money. On the other hand, if too little inventory is kept, it could mean that some customers won't receive what they want.

A well-planned inventory replenishment program helps businesses save money and improve service levels.

Inventory Replenishment vs Inventory Control

The inventory replenishment process is often confused with inventory control. In fact, there are many differences between the two processes. Let’s take a look at some of the most important ones.

Level of Stock and Reorder Quantity

First, inventory replenishment is about optimizing what you sell. This includes everything from how much inventory you keep to where it goes. On the other hand, inventory control is about controlling what you sell. This involves things like keeping track of stock levels, managing warehouse space, and ensuring that you don’t run out of product.

Inventory Policy Decisions

Second, inventory replenishment is usually done manually. You might use Excel spreadsheets to manage your current stock level, or you could even write down every item you want to buy. However, inventory control is almost always automated. For example, you can set up a system that automatically sends you an email whenever you reach a certain safety stock level of inventory. This is called the top-off method.

Third, inventory replenishment is focused on selling products. Inventory control is focused on buying products. If you’re running low on something, you’ll probably go ahead and purchase more of it. But if you’ve already sold enough, you won’t bother purchasing anymore.

Quantity of Stockout and Inventory Replenishment Models

Fourth, inventory replenishment is based on sales demand and touches on demand forecasts. Inventory control is based on supply. When you know that customers are going to come looking for your product, you’ll make sure that you have plenty of it. But if no one is asking for it, you won’ t worry too much about whether or not you have enough, your maximum stock level for that particular product can be very low.

Fifth, inventory replenishment is reactive. Inventory control is proactive. If someone asks for a specific product, you’re likely to find out about it sooner rather than later. And if you don’t have enough, you’ll go out and buy more. But if nobody asks for a particular product, you won’ re notice that you’re short until you actually run out.

Sixth, inventory replenishment takes place over time. Inventory control happens immediately. You either have enough or you don’t. There’s nothing else to consider.

How inventory replenishment works

Inventory replenishment is an important aspect of any organization's operations, especially those that deal with perishable goods.

Traditional Safety Stock Model

There are two main ways that companies replenish their inventories: directly from suppliers and through distributors, or wholesalers. Wholesalers buy products from manufacturers and sell them to retailers. They do this because it allows them to offer lower prices to consumers. This makes sense since they don't pay for transportation costs like retailers do. However, there are some drawbacks to working with wholesalers. For one thing, you'll often find yourself dealing with multiple wholesalers, each of whom might have different terms. You could end up paying more for shipping than you did buying locally. Another problem is that wholesalers aren't always able to provide exactly what you want. If you're looking for something specific, you might have to settle for whatever they happen to have in stock.

The best way to avoid these problems is to work directly with suppliers. Suppliers usually have better pricing and fewer middlemen. In addition, they know how much product they have left over from previous shipments. This information helps them make sure they never run out of stock.

Inventory Replenishment Explained

Inventory replenishment is an important aspect of supply chain management, as it involves balancing the needs of maintaining an adequate supply of goods to meet customer demand with the goal of minimizing waste and maximizing sustainability. The Journal of the Korean Society of Supply Chain Management has published numerous articles on this topic, highlighting the importance of considering various factors such as days of stock, spike quantity, and time distributions in order to optimize inventory replenishment.

One approach to inventory replenishment is to use agile supply techniques, which involve a more flexible and responsive approach to managing the flow of goods through the supply chain. This can involve the use of collaborative supply strategies, in which multiple companies work together to share resources and information in order to more efficiently meet customer demand.

In order to effectively manage inventory replenishment, it is important to consider the variability factor, which refers to the amount of uncertainty involved in predicting customer demand. The T-SS (time between successive shortages) and safety factor are two tools that can be used to help mitigate this uncertainty, by helping to determine the optimal safety factor (the amount of inventory that should be kept on hand in order to prevent shortages) based on time factors and other relevant data.

Operations research techniques can also be used to analyze and optimize inventory replenishment processes, using computational tools such as computers and software to model and simulate different scenarios in order to determine the most effective strategies. By considering these and other factors, companies can work to improve the efficiency and sustainability of their inventory replenishment processes, helping to ensure that they are able to meet the needs of their customers while minimizing waste and maximizing the use of resources.

The process of replenishing inventory is one of the most important tasks facing every manager. If you don't know how to do it correctly, you could end up losing money. In fact, according to a recent study conducted by the National Retail Federation, nearly half of retailers surveyed lost money due to overstocking.

The Traditional Safety Stock Formula Is No Longer Enough

Paper-based systems are inefficient and often lead to mistakes. They're also difficult to manage because there's no way to see what items are missing without manually checking each item against the list. This makes it easy to forget about something important.

Dynamic Simulation and Accurate Demand Models With AI

Technology offers a better solution. With inventory management software, you can easily monitor inventory levels and make sure you never run out of anything. You can even set alerts to notify you when certain products reach low stock levels.

Cloud Inventory Management

Automating the process of replenishing inventory saves you time and money. For example, some companies use barcode scanners to scan items as they come off the production lines. Then, they automatically add those items to the appropriate shelves. Others centralise everything in the cloud through one, integrated AI-driven-system, that keeps all departments up to date with real-time inventory data.

Replenishment-Based and Forecast-Based Inventory Policies

Inventory replenishment is an important aspect of keeping a healthy supply chain. When products run out, customers stop buying, sales decline, and profits plummet. To avoid this scenario, companies must maintain enough stock to meet demand. This requires accurate forecasting of future demand, which is why most businesses use some form of inventory management software.

Calculating Inventory the Inventory Management Method

There are many different ways to calculate how much inventory to order based on current sales levels. These include:

1. Ordering too little (demand in inventory)

If you don't order enough product, you won't have enough to sell when customers want it. You'll lose money because you're selling less than you could.

2. Ordering too much (excessive inventory)

- If you buy too much product, you'll end up paying for storage space you don't need. Plus, you'll have excess inventory sitting around doing nothing.

3. Ordering too soon (excessive delivery lead time)

If you wait too long to order, you risk running out of product before you've sold everything you bought. Customers might start complaining about slow delivery times and poor customer service.

4. Ordering too late (potential cash flow issues)

If you order too much product too early, you'll find yourself ordering even more later when you realize you still have plenty left over.

5. Ordering just enough

If you order too little, you'll miss out on potential revenue. But if you order too much, you'll waste money storing unsold inventory.

Factors That Impact Inventory Replenishment Methods

Inventory replenishment planning should include a thorough analysis of the current state and processes of the warehouse and its systems. This includes understanding how the warehouse works and what it takes to keep things running smoothly. Such as:

- shipping costs

- sales channels

- average quantity

- replenishment order quantity

- average shortage quantity

- average lead times

- average inventory levels

- normal distribution

- realistic distribution

- alternative distributions

- daily lead time

- medium lead time

- replenishment lead time

- shortage costs

All these factors and more go into an effective Strategic inventory model, and takes it from being a reactive business to a forward thinking enterprise.

Additional Forecasting Factors

In addition, you must consider the external factors affecting the warehouse such as weather conditions, customer demand, and seasonal changes.

Inventory Replenishment Methods

There are many different ways to plan inventory replenishment, each with pros and con. Some of the most common approaches include:

Fixed cycle

Fixed cycle inventory replenishment restocks inventories at regular periods. This strategy entails setting a replenishment plan, such as weekly or monthly.

Fixed cycle inventory replenishment is utilised in stable, predictable businesses. It's an excellent approach to ensuring a business has enough inventory to fulfil client demand without regular human modifications.

Fixed-cycle inventory replenishment may not be suited for organisations with considerable demand swings or a highly unstable supply chain. Just-in-time inventory or demand-driven replenishment may be more appropriate in some circumstances.

Variable cycle

flexible It involves adjusting inventory replenishment based on demand.

If a product has strong and fluctuating demand, a corporation may choose variable cycle inventory replenishment to meet demand and avoid running out of stock or having excess inventory. If product demand is consistent and predictable, a corporation may choose a fixed cycle inventory replenishment strategy, where inventory is replenished at regular intervals regardless of demand.

Variable cycle inventory replenishment can be used alongside reorder points and demand forecasts to guarantee a business has enough inventory to meet consumer demand and function efficiently.

Demand driven

Demand-driven inventory replenishment is based on actual consumer demand, not forecasts or other predictive approaches. In a demand-driven replenishment system, inventory is only refreshed to meet consumer orders. This reduces excess inventory, storage expenses, and stock outs.

JIT and VMI systems can be utilised to implement demand-driven inventory replenishment. JIT systems rely on regular, small inventory deliveries to fulfil demand, while VMI systems have the supplier or manufacturer manage a store or distributor's inventory.

Demand-driven inventory replenishment can optimise inventory levels and decrease costs, but it requires knowledge into demand patterns and the capacity to respond swiftly to changes. It's employed with forecasting and safety stock.

Seasonal

Seasonal inventory replenishment restocks or refills inventories to satisfy seasonal demand. This type of inventory replenishment is commonly needed for enterprises that sell holiday presents or summer trip supplies.

Businesses may need to change inventory levels and replenishment plans for seasonal demand. This may involve raising inventory levels before the busiest season, offering special promotions or discounts, and applying demand forecasting tools.

Effective seasonal inventory replenishment helps firms satisfy increased demand during busiest seasons of the year without overstocking or running out of products.

Stock rotation

First-in, first-out (FIFO) inventory management sells or uses the oldest products first. This method is used to ensure perishable commodities, such as food and drinks, are used before expiration.

Stock rotation ensures older inventory is used or sold before new inventory is added. This reduces waste and extra inventories.

Physically rotating shelves or using computer systems to track and manage inventory are two ways to rotate goods. It's utilised with forecasting and just-in-time inventory systems to optimise inventory levels and boost efficiency.

Stock Policy">Open Stock Policy

A retailer maintains a large quantity of products in stock at all times. When demand increases, additional inventory is added to meet customer needs. If there isn’t enough inventory to satisfy customers, the retailer must either reduce prices or close stores.

Minimum Order Quantity Policy">Minimum Order Quantity Policy

A retailer keeps a small quantity of products in stock. When demand increases, the retailer adds additional inventory to meet customer needs. However, if there isn’t sufficient inventory to fulfill customer demands, the retailer must raise prices or close stores. This method is typically used by smaller retailers because it requires less capital investment.

Stock Picking Method">Stock Picking Method

A retailer selects items from a warehouse to fill specific customer orders. Once the order is filled, the item is removed from the warehouse. This method is commonly used by larger retailers because it allows them to quickly respond to changing market conditions.

Your company's forecast has fluctuated

The world economy is changing rapidly, and it affects everyone. In fact, according to the World Economic Forum, the global economic outlook is worse than we thought just six months ago. This makes it important to understand how companies like yours are coping with the current situation.

Inventory Replenishment Best Practices

Retailers are always looking for ways to improve operations and increase efficiency. One area where many businesses struggle is maintaining adequate inventory levels. In fact, according to a recent study conducted by RetailMeNot, nearly half of small and medium-sized businesses surveyed reported having run out of stock at least once over the previous 12 months. This can lead to lost sales and unhappy customers.

The good news is that there are some simple best practices you can use to help ensure that you never run out of stock again. Here are five tips to help you manage your inventory better:

1. Determine What Will Happen If Inventory Runs Out

Before you even start stocking up on products, it’s important to know how much inventory you actually need. You want to make sure you have enough product to meet customer demand while still ensuring that you won’t run out. To do this, you must determine what will happen if inventory does run out. For example, if you sell clothing items, you might consider whether people will buy something else or simply wait until you restock.

2. Develop A Plan To Deal With Those Situations

Once you know what will happen if inventory goes low, you can develop a plan to deal with that scenario. For instance, if you find yourself running low on certain types of merchandise, you could contact suppliers to see if they can provide additional supplies. Or, if you notice that your customers are buying less frequently, you could offer discounts to encourage purchases.

3. Assess and re-assess your forecast

The best way to prepare for the coming year is to look at the current state of the market and make adjustments based on those findings. This is especially true for retailers who are looking to expand into new markets. If you're planning to open up shop in another city, it's important to understand the local economy and consumer habits. You'll want to know whether there's enough demand for your products in that area. And if you're thinking about expanding internationally, you'll want to know where your competitors are located and what type of competition you might face.

Formulate effective stocking level strategies

Stocking levels are one of the most important factors in determining how much inventory you'll need to buy. But it's easy to overlook some key considerations when setting up your strategy. Here are three things to keep in mind when developing your plan.

1. Determine your capacity

The first step is to determine your current capacity. This includes everything from your physical space to your staffing needs. If you're planning to add employees, consider what type of training they'll require, whether there are additional resources needed, and how long it takes to train someone. You'll also want to know how many hours each employee works per week, and how many days off they take.

2. Consider your future growth

Once you've determined your capacity, think about where you'd like to grow. Do you anticipate adding more locations? Or do you plan to increase your workforce size? How quickly does your business expand? These questions help you figure out how much inventory you'll likely need over the next few months.

3. Factor in seasonal fluctuations

Finally, don't forget to account for seasonal fluctuations. For example, if you sell clothing during the summer, you might need to purchase extra inventory during those months. Conversely, if you sell shoes during winter, you'll probably need fewer pairs of boots in the fall.

Create better end-to-end visibility

Make sure everyone in your supply chain knows where your inventory is. This comprises warehouse workers, shippers, carriers, distributors, and retailers. Unknown inventory is hard to manage.

Inventory visibility is a major corporate concern. Nearly half of firms questioned by Forrester Research reported difficulty controlling inventory. And it's not just big businesses. Similar challenges plague small firms.

What is inventory visibility? Consider: Imagine a room filled with boxes. Find each box. What would you do? You might check each box for "Made in China" or "Sold Out." Or you could ask for help. Ask the person who assembled the crates where everything is.

Your warehouse space is not optimised

Warehouse space planning is an important aspect of any warehouse management system (WMS). This includes determining what type of storage you need and where it should go. You must consider the needs of your customers and make sure that there is enough room for everything.

There are several different types of storage spaces within a warehouse. These include:

• Shelving – Used to store products

• Racking – Used to organize items into rows

• Bins – Used to hold smaller quantities of inventory

• Pallets – Used to transport goods

• FIFO – First In/First Out - Used to determine the best way to stock inventory

The quantity of space needed depends on the number of SKUs, product size, sales frequency, and demand.

A good WMS helps plan your warehouse's layout.

Inventory visibility is a method that helps employees find and identify things. Visibility helps you avoid overstocking or understocking and makes inventory tracking easier.

Many firms struggle to establish inventory visibility because they lack the necessary technologies. Inventory Insight was created to overcome this problem. Inventory Insight automates inventory tracking across warehouses, distribution centres, retail stores, and ecommerce sites. Inventory Insight may decrease expenses, boost efficiency, and streamline operations.

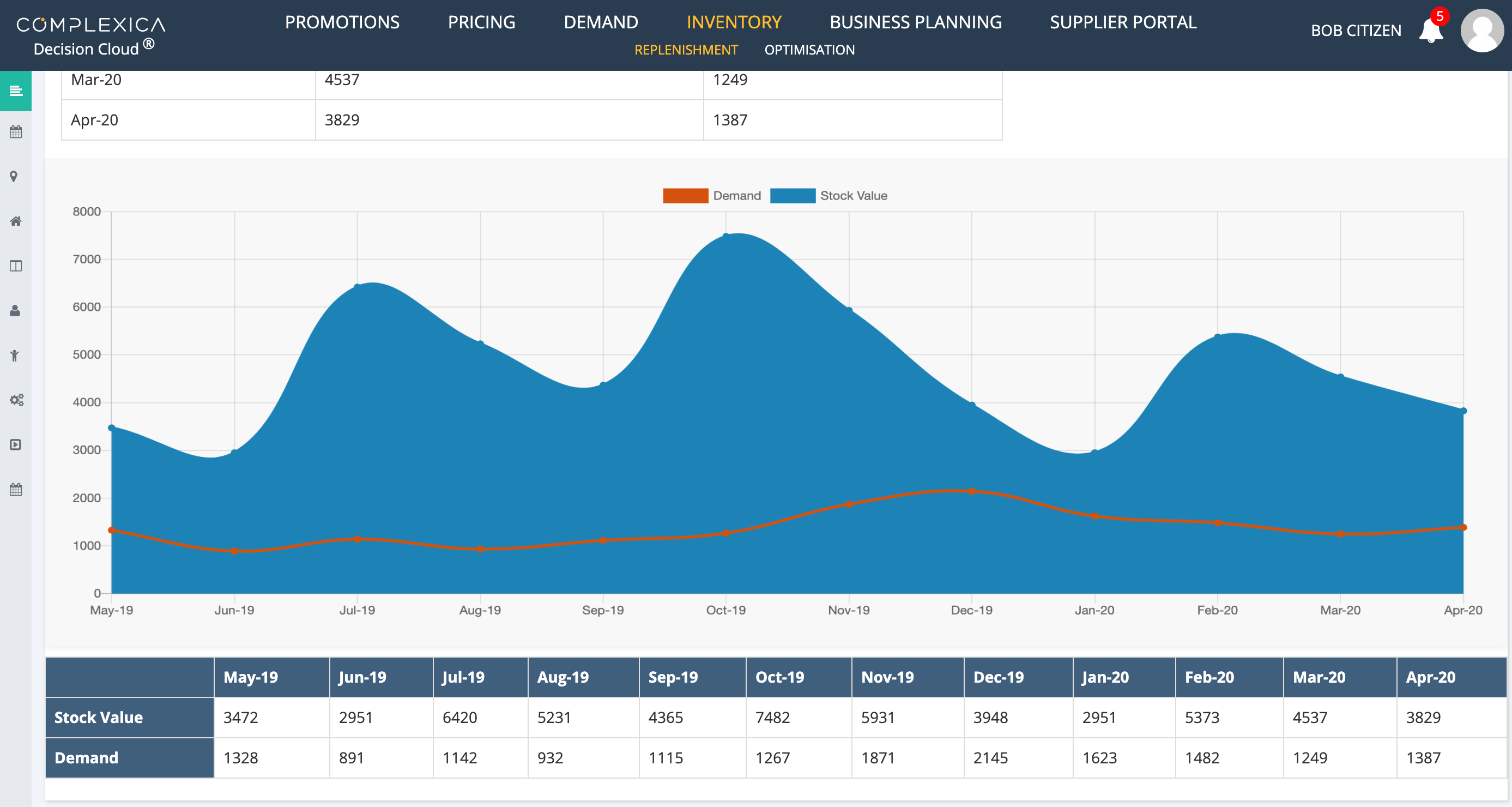

Supply & Demand Planner is a module of our Decision Cloud® software platform, which offers a number of tangible benefits for manufacturers, distributors, and retailers, including:

- Improved forecast accuracy, which is particularly important for hard-to-forecast product lines

- Reduced inventory levels

- Reduced stockouts, leading to a corresponding increase in customer fill rates (as measured by Delivery In Full, On Time metrics, “DIFOT”)

- Less time and effort for planning inventory and replenishment

To explore how our Supply & Demand Planner can help you optimise your supply chain activities, please contact us

INVENTORY REPLENISHMENT REFERENCES

inventory data inventory management cost supply chain warehouse retail technology safety stock inventory control quantity ecommerce inventory management software demand forecasting automation stockouts visibility warehouses 3pl order fulfillment stockout price b2b economic order quantity b2c definition bullwhip effect just-in-time enterprise resource planning warehouse management systems opportunity cost warehouse management system profit margins realtime third-party logistics

ADDITIONAL TOPICS COVERED

Multi,last,source,change,integrations,partner,sale,analytics,brands,team,optimization,report,partners,insights,channel,operational,success,centers,australia,to reorder,efficient,supply chain management,periodic,reporting,profitability,opportunities,order management,replenish inventory,point,right time,reorder point,stock replenishment process,customer satisfaction,effective inventory replenishment,replenishment template,reserve storage,daily usage,replenishment orders,inventory replenishment strategies,inventory items,brand,profitability,warehousing,business logistics,surplus,supply chain management,inventory management systems,inventory optimization,last-mile delivery,inventoro,logistical,logistics management,holding costs,brick-and-mortar,obsolete.

Inventory position,time forecast,inventory from reserve storage,Safety stock performance simulation,Statistical Forecasting for Inventory Control,Supply Chain Management at Warp Speed,shorter lead time.Study of demand,parameter value range,range of parameter values,valid range,planning period,individual items,item characteristics,stories from companies,interpolation from Table,time in Table,Business Logistics/Supply Chain Management,Business Central,comparative analysis,Mathematical analysis,Adjusted Sales Velocity.Lognormal distribution,cumulative distribution function values,Supply Chain Management and Sustainability,T-SS,safety factor,Computers and Operations Research,Computers & Operations Research.

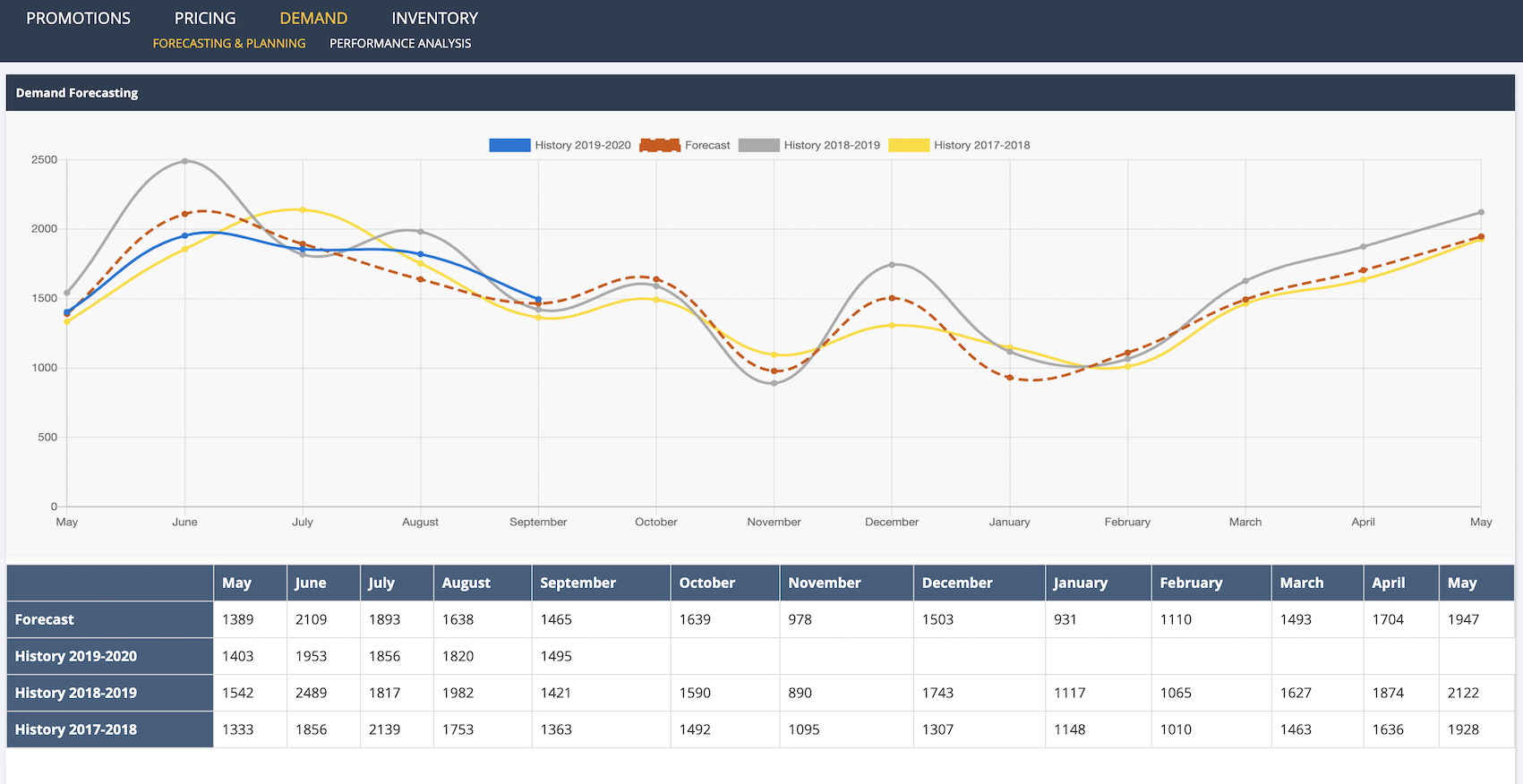

The reason for this is that demand forecasting is a scientific problem of using algorithms and data to predict what will happen in the future with some level of accuracy (rather than a software problem of features and functionality). To improve this prediction accuracy, Complexica’s Demand Planner relies upon a variety of statistical and non-statistical models within an ensemble model (rather than just standard statistical models like most demand forecasting applications), with each model attempting to generate the most accurate forecast possible and then learning from actual results. This process is further enhanced by using external data (which may vary from industry to industry) to increase the amount of variables each model considers. The result is a more accurate prediction, which leads to optimised inventory, working capital, and replenishment decisions.

Demand Planner is a module of our Decision Cloud® software platform, which offers a number of tangible benefits for manufacturers, distributors, and retailers, including:

- Improved forecast accuracy, which is particularly important for hard-to-forecast product lines

- Reduced inventory levels

- Reduced stockouts, leading to a corresponding increase in customer fill rates (as measured by Delivery In Full, On Time metrics, “DIFOT”)

- Less time and effort for planning inventory and replenishment

Learn how PFD Foods automates and optimises its demand planning and replenishment activities

To explore how our Demand Planner can help you optimise your supply chain activities, please contact us

"Larry will be our digital expert that will enable our sales team and add that technological advantage that our competitors don't have."

Kerry Smith

CEO, PFD Foods

$1.6 billion in revenue

"Lion is one of Australasia’s largest food and beverage companies, supplying various alcohol products to wholesalers and retailers, and running multiple and frequent trade promotions throughout the year. The creation of promotional plans is a complicated task that requires considerable expertise and effort, and is an area where improved decision-making has the potential to positively impact the sales growth of various Lion products and product categories. Given Complexica’s world-class prediction and optimisation capabilities, award-winning software applications, and significant customer base in the food and alcohol industry, we have selected Complexica as our vendor of choice for trade promotion optimisation."

Mark Powell

National Sales Director, Lion

"At Liquor Barons we have an entrepreneurial mindset and are proud of being proactive rather than reactive in our approach to delivering the best possible customer service, which includes our premier liquor loyalty program and consumer-driven marketing. Given Complexica’s expertise in the Liquor industry, and significant customer base on both the retail and supplier side, we chose Complexica's Promotional Campaign Manager for digitalizing our spreadsheet-based approach for promotion planning, range management, and supplier portal access, which in turn will lift the sophistication of our key marketing processes."

Richard Verney

Marketing Manager

Liquor Barons

"Dulux is a leading marketer and manufacturer of some of Australia’s most recognised paint brands. The Dulux Retail sales team manage a diverse portfolio of products and the execution of our sales and marketing activity within both large, medium and small format home improvement retail stores. We consistently challenge ourselves to innovate and grow and to create greater value for our customers and the end consumer. Given the rise and application of Artificial Intelligence in recent times, we have partnered with Complexica to help us identify the right insight at the right time to improve our focus, decision making, execution, and value creation."

Jay Bedford

National Retail Sales Manager

Dulux

"Following a successful proof-of-concept earlier this year, we have selected Complexica as our vendor of choice for standardizing and optimising our promotional planning activities. Complexica’s Promotional Campaign Manager will provide us with a cloud-based platform for automating and optimising promotional planning for more than 2,700 stores, leading to improved decision-making, promotional effectiveness, and financial outcomes for our retail stores."

Rod Pritchard

Interim CEO, Metcash - Australian Liquor Marketers

$3.4 billion in revenue

"After evaluating a number of software applications and vendors available on the market, we have decided to partner with Complexica for sales force optimisation and automation. We have found Complexica’s applications to be best suited for our extensive SKU range and large set of customers, being capable of generating recommendations and insights without burdening our sales staff with endless data analysis and interpretation.

Aemel Nordin

Managing Director, Polyaire

"DuluxGroup is pleased to expand its relationship with Complexica, a valued strategic partner and supplier to our business. Complexica’s software will enable DuluxGroup to reduce the amount of time required to generate usable insights, increase our campaign automation capability, personalise our communications based on core metrics, and close the loop on sales results to optimise ongoing digital marketing activity."

James Jones

Group Head of CRM, DuluxGroup

"Instead of hiring hundreds of data scientists to churn through endless sets of data to provide PFD with customer-specific insights and personalised recommendations, Larry, the Digital Analyst® will serve up the answers we need, when we need them, on a fully automated basis without the time and manual processes typically associated with complex analytical tasks.”

Richard Cohen

CIO, PFD Foods

$1.6 billion in revenue

"As a global innovator in the wine industry, Pernod Ricard Winemakers is always seeking ways to gain efficiencies and best practices across our operational sites. Given the rise of Artificial Intelligence and big data analytics in recent times, we have engaged Complexica to explore how we can achieve a best-in-class wine supply chain using their cloud-based software applications. The engagement is focused on Australia & New Zealand, with a view to expand globally."

Brett McKinnon

Global Operations Director, Pernod Ricard Winemakers

"70% - 80% of what we do is about promotional activity, promotional pricing -- essentially what we take to the marketplace. This is one of the most comprehensive, most complex, one of the most difficult aspect of our business to get right. With Complexica, we will be best in class - there will not be anybody in the market that can perform this task more effectively or more efficiently than we can."

Doug Misener

CEO, Liquor Marketing Group

1,400+ retail stores

"The key thing that makes such a difference in working with Complexica is their focus on delivering the business benefits and outcomes of the project."

Doug Misener

CEO, Liquor Marketing Group

1,400+ retail stores

"Australia needs smart technology and people, and it has been a great experience for me to observe Complexica co-founders Zbigniew and Matt Michalewicz assemble great teams of people using their mathematical, logic, programming, and business skills to create world-beating products. They are leaders in taking our bright graduates and forging them into the businesses of the future."

Lewis Owens

Chairman of the Board, SA Water

"Having known the team behind Complexica for some years ago now, I am struck by their ability to make the complex simple - to use data and all its possibilities for useful purpose. They bring real intelligence to AI and have an commercial approach to its application."

Andrew McEvoy

Managing Director, Fairfax Media - Digital

"I have worked with the team at Complexica for a number of years and have found them professional, innovative and have appreciated their partnership approach to delivering solutions to complex problems."

Kelvin McGrath

CIO, Asciano

“Working with Complexica to deliver Project Automate has been a true partnership from the initial stages of analysis of LMG’s existing processes and data handling, through scoping and development phase and onto delivery and process change adoption. The Complexica team have delivered considerable value at each stage and will continue to be a valued partner to LMG."

Gavin Saunders

CFO, Liquor Marketing Group

“Complexica’s Order Management System and Larry, the Digital Analyst will provide more than 300 Bunzl account managers with real-time analytics and insights, to empower decision making and enhanced support. This will create more time for our teams to enable them to see more customers each day and provide the Bunzl personalised experience.”

Kim Hetherington

CEO, Bunzl Australasia

"The team behind Complexica develops software products that are at the cutting edge of science and technology, always focused on the opportunities to deliver a decisive competitive edge to business. It has always been a great experience collaborating with Matthew, Zbigniew and Co."

Mike Lomman

GM Demand Chain, Roy Hill Iron Ore

"The innovations that the Complexica team are capable of continue to amaze me. They look at problems from the client side and use a unique approach to collaborating with and deeply understanding their customers challenges. This uniquely differentiates what they bring to market and how they deliver value to customers."

John Ansley

CIO, Toll Group

"Rather than building out an internal analytics team to investigate and analyse countless data sets, we have partnered with Complexica to provide our sales reps with the answers they need, when they need them, on a fully automated basis. We are excited about the benefits that Larry, the Digital Analyst will deliver to our business.”

Peter Caughey

CEO, Coventry Group

“Complexica’s Order Management System and Larry, the Digital Analyst will provide more than 300 Bunzl account managers with real-time analytics and insights, to empower decision making and enhanced support. This will create more time for our teams to enable them to see more customers each day and provide the Bunzl personalised experience.”

Kim Hetherington

CEO, Bunzl Australasia

"After an evaluation process and successful proof-of-concept in 2016, we have chosen to partner with Complexica to upgrade the technological capability of our in-field sales force. The next-generation Customer Opportunity Profiler provided by Complexica will serve as a key tool for sales staff to optimise their daily activities, personalise conversations and interactions with customers, and analyse data to generate actionable insights."

Stephen Mooney

Group Sales Capability Manager, DuluxGroup

$1.7 billion in revenue

"After evaluating a number of software systems available in the marketplace, we have ultimately selected Complexica as our vendor of choice for sales force automation and CRM. Given the large SKU range we carry and very long tail of customers we serve, Complexica’s applications are best suited to deal with this inherent complexity without burdening our staff with endless data entry."

Nick Carr

CEO, Haircaire Australia

Australia's largest distributor of haircare products

“Asahi Beverages is Australia’s largest brewer, supplying a leading portfolio to wholesalers and retailers, including some of Australia’s most iconic brands. Last year Asahi Beverages acquired Carlton & United Breweries, which is its Australian alcohol business division. To harness the strength of our expanded portfolio, we partner with our customers to run multiple and frequent trade promotions throughout the year, delivering long-term growth for both our business and theirs. Given the inherent complexity in optimising promotional plans and our continued focus on revenue and growth management, we have selected Complexica as our vendor of choice after a successful Proof-of-Concept of its world-class optimisation capabilities.”

Kellie Barnes

Group Chief Information Officer

Asahi Beverages

"Dulux is a leading marketer and manufacturer of some of Australia’s most recognised paint brands. The Dulux Retail sales team manage a diverse portfolio of products and the execution of our sales and marketing activity within both large, medium and small format home improvement retail stores. We consistently challenge ourselves to innovate and grow and to create greater value for our customers and the end consumer. Given the rise and application of Artificial Intelligence in recent times, we have partnered with Complexica to help us identify the right insight at the right time to improve our focus, decision making, execution, and value creation."

Jay Bedford

National Retail Sales Manager, DuluxGroup

"At Liquor Barons we have an entrepreneurial mindset and are proud of being proactive rather than reactive in our approach to delivering the best possible customer service, which includes our premier liquor loyalty program and consumer-driven marketing. Given Complexica’s expertise in the Liquor industry, and significant customer base on both the retail and supplier side, we chose Complexica's Promotional Campaign Manager for digitalizing our spreadsheet-based approach for promotion planning, range management, and supplier portal access, which in turn will lift the sophistication of our key marketing processes."

Richard Verney

Marketing Manager, Liquor Barons